| |

Machine_Parts_Index Power Screws

More details on Power Screw design are to be found in the links below the table

|

Introduction Power Screws are used for providing linear motion in a smooth uniform manner.

They are linear actuators that transform rotary motion into linear motion. Power screws

are are generally based on Acme , Square, and Buttress threads. Ball screws are

a type of power screw. Efficiencies of between 30% and 70% are obtained with

conventional power screws. Ball screws have efficiencies of above .

And excel based calculator for power screws is available with subscription from ExcelCalcs.com calculation Power Screw.xls Calculations for power screws Square Form This form is used for power/force transmission i.e. linear jacks, clamps. The friction

is low and there is no radial forces imposed on the mating nuts. The square thread is the most

efficient conventional power screw form. It is the most difficult form to machine.

It is not very compatible for using split nuts-as used on certain machine tool system for withdrawing

the tool carriers

Acme Form Used for power transmission i.e. lathe lead screws. Is easier to manufacture compared to a square thread. It has superior root strength characteristics compared to a square thread. The acme screw thread has been developed for machine tool drives. They are easy to machine and can be used with split nuts. The thread has an optimum efficiency of about 70% for helix angles between 25o and 65o. Outside this range the efficiency falls away.

Buttress Form A strong low friction thread. However it is designed only to take large loads in on direction. For a given size this is the strongest of the thread forms. When taking heavy loads on the near vertical thread face this thread is almost as efficient as a square thread form.

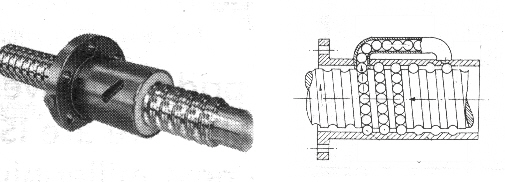

Recirculating Ball Screw This type of power screw is used for high speed high efficiency duties.

The ball screw is used for more and more applications previously completed by the conventional

power screws.

The recirculated ball screw has the following advantages and disadvantages to the conventional threaded power screws: Advantages

A recent high specification power screw option is the roller screw. For this unit the nut includes a number of special threaded rollers arranged around arround the central screw. The rollers each take a part of the load. This system is efficient and can withstand high loads. |

Links to Power Screw Design

|

|