Machine_Parts_Index

Spring Index Helical Spring Design

Introduction....

Nomenclature....

Spring Index ....

Spring Rate....

Spring Stress Values....

Compression Spring Formula....

Compression Spring End Designs ....

Extension Springs....

Rectangular Section Springs....

Conical Helical Springs....

|

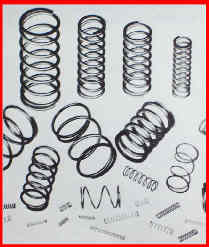

INTRODUCTION A helical spring is a spiral wound wire with a constant coil diameter and uniform pitch.

The most common form of helical spring is the compression spring but tension springs are also widely used.

. Helical springs are generally made from round wire... it is comparatively rare

for springs to be made from square or rectangular sections. The strength of the steel used

is one of the most important criteria to consider in designing springs. Most helical

springs are mass produced by specialists organisations. It is not recommended that

springs are made specifically for applications if off-the-shelf springs can be obtained to

the job.

Nomenclature

Note: metres (m) have been shown as the units of length in all of the variables above

for consistency. In most practical calculations milli-metres will be more

convenient.

Spring Index The spring index (C) for helical springs in a measure of coil curvature ..

For most helical springs C is between 3 and 12 Spring Rate Generally springs are designed to have a deflection proportional to the applied load (or torque -for torsion springs). The "Spring Rate" is the Load per unit deflection.... Rate (N/mm) = F(N) / δ e(deflection=mm)

Spring Stress Values For General purpose springs a maximum stress value of 40% of the steel tensile stress may be used. However the stress levels are related to the duty and material condition (ref to relevant Code/standard). Reference Webpage Spring Materials Compression Springs- Formulae a) Stress

Consider a compression spring under an axial force F. If a section through a single wire is taken it can be seen that, to maintain equilibrium of forces, the wire is transmits a pure shear load F and also to a torque of Fr.

The stress in the wire due to the applied load =

This equation is simplified by using a traverse shear distribution factor K d = (C+0,5)/C.... The above equation now becomes.

The curvature of the helical spring actually results in higher shear stresses on the inner surfaces of the spring than indicated by the formula above. A curvature correction factor has been determined ( attributed to A.M.Wahl). This (Wahl) factor K w is shown as follows.

This factor includes the traverse shear distribution factor K d.. The formula for maximum shear stress now becomes.

A table relating KW to C is provided below

b) Deflection

The spring axial deflection is obtained as follows.

Replacing T= FD/2, l = πDn, A = πd2 /4 The formula becomes.

Using Castiglianos theorem to find the total strain energy....

Substituting the spring index C for D/d The formula becomes....

In practice the term (1 + 0,5/C2) which approximates to 1 can be ignored

In practice the term (C2 /(C2 + 0,5)) which approximates to 1 can be ignored Compression Spring End Designs The figure below shows various end designs with different handing.

Each end design can be associated with any end design. The plain ends are not desirable for springs which are highly loaded or for

precise duties.

The table below shows some equations affected by the end designs...

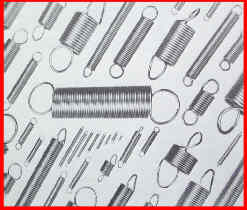

Helical Extension Springs

The formulae provided for the compression springs generally also apply to extension

springs.

An Extension spring is sometimes tightly wound such that it is prestressed with an initial stress τ i . This results in the spring having a property of an initial tension which must be exceeded before any deflection can take place. When the load exceeds the initial tension the spring behaves according the the formulae above. This relationship is illustrated in the figure below

The initial tension load can be calculated from the formula.... T i = π τ i d 3/ ( 8 D) Best range of of Initial Stress (τ i) for a spring related to the Spring Index C = (D/d)

If the coils in a tension spring are not tightly wound, there is

no initial tension and the relevant equations are identical to those for the spring

under compression as identified above.

Helical Compression Springs (Rectangular Wire)

Spring Rate and Stress

Conical Helical Compression Springs

These are helical springs with coils progressively change in diameter to give increasing

stiffness with increasing load. This type of spring has the advantage that its

compressed height can be relatively small. A major user of conical springs is

the upholstery industry for beds and settees.

Allowable Force on Spring...

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Links to Spring Design

|

|

Machine_Parts_Index

Spring Index

>

>